Aquaculture Raw Water Treatment System B

Seawater is pumped from the seaside pumping station to the sedimentation tank, where sodium hypochlorite or chlorine dioxide is added to the inlet pipe.

Classification:

Product Center

Aquatic Products and Aquariums Series

Aquaculture Raw Water Treatment

Key words:

Aquaculture Raw Water Treatment System B

Aquaculture Raw Water Treatment System B Details

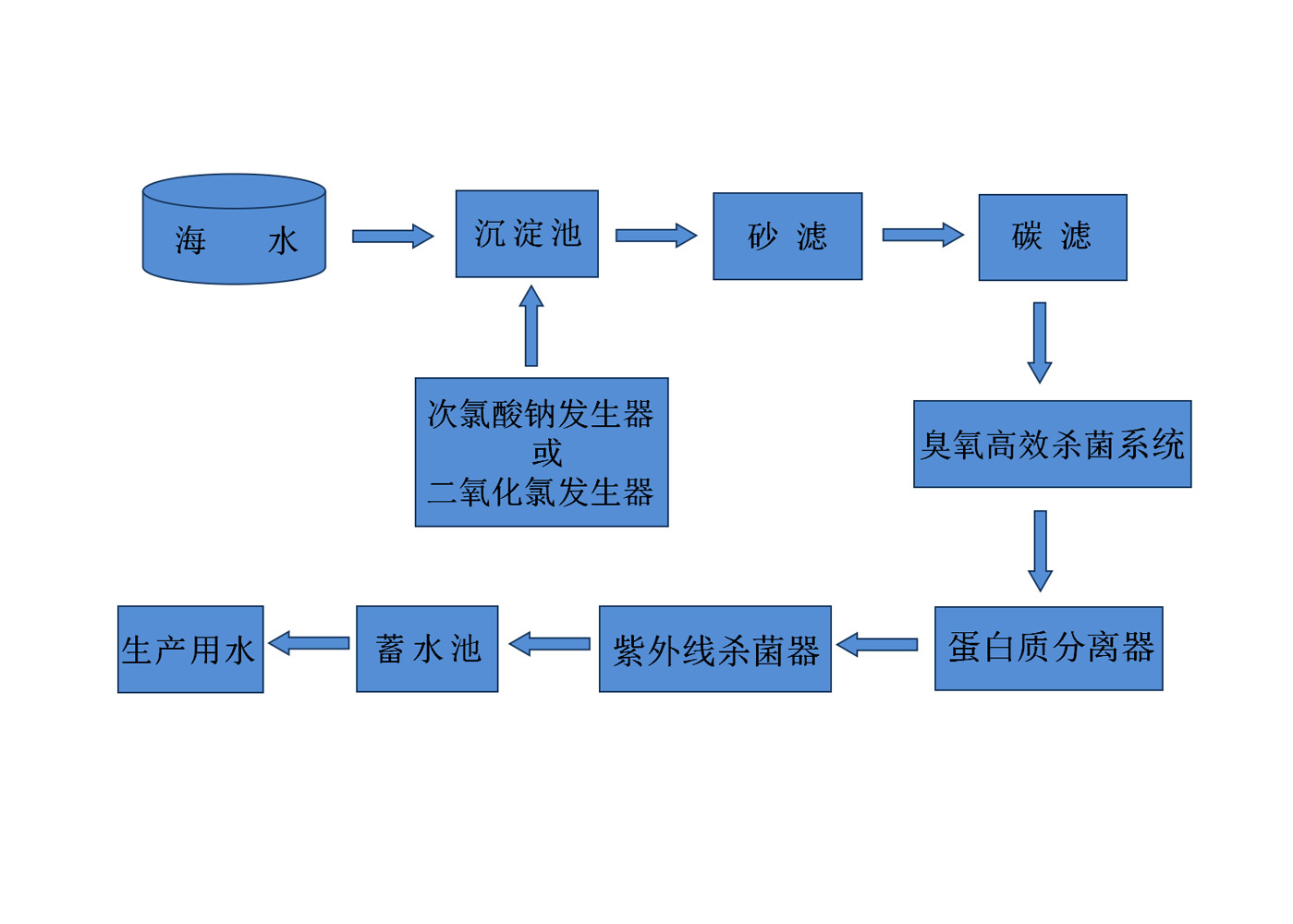

Introduction to the seawater treatment process B of the aquaculture raw water treatment system

Seawater is pumped from the seaside pumping station to the sedimentation tank, where sodium hypochlorite or chlorine dioxide is added to disinfect and settle the seawater in the sedimentation tank. Sodium hypochlorite or chlorine dioxide has a broad-spectrum, efficient, and low-toxicity effect on killing pathogenic microorganisms, effectively preventing and controlling the occurrence of various bacteria, fungi, and spore diseases. After disinfection and sedimentation in the sedimentation tank, the seawater enters the sand filter and carbon filter in sequence. The sand filter and carbon filter are filled with multiple layers of quartz sand and activated carbon, respectively, which can effectively remove suspended solids, organic matter, microorganisms, chlorine, heavy metal ions, odors, and other substances from the seawater. The water from the carbon filter enters the ozone high-efficiency sterilization system, where it undergoes disinfection with high concentrations of ozone before entering the protein separator. The protein separator can separate over 80% of the organic matter from the water and increase the dissolved oxygen content in the water. The water from the protein separator enters the ultraviolet sterilizer for disinfection before entering the water storage tank for production use.

System composition flow chart

Applications

This process is suitable for the raw water treatment of seawater factory farming or the raw water treatment of seedling production in coastal areas with relatively good seawater quality.

System features

1. Design scheme based on water quality

2. Low equipment energy consumption and operating costs

3. Simple process flow, easy to operate and manage

4. Stable operation with low maintenance costs

5. High degree of automation, stable water quality meeting standards

Introduction to related equipment of the system

① Chlorine dioxide generator or sodium hypochlorite generator:

Chlorine dioxide and sodium hypochlorite, as broad-spectrum, non-toxic, and efficient disinfectants, can effectively kill Vibrio and various harmful bacteria, and are widely used in the aquaculture industry. The chlorine dioxide generator or sodium hypochlorite generator can prepare chlorine dioxide or sodium hypochlorite disinfectant on-site, ready for use, significantly reducing the cost of disinfectants while minimizing the risks associated with disinfectant transportation.

② Sand filter and carbon filter.

Can effectively remove suspended solids, organic matter, microorganisms, chlorine, heavy metal ions, odors, etc. from seawater.

③ Ozone high-efficiency sterilization system:

The ozone high-efficiency sterilization system consists of a high-concentration ozone generator, ozone high-efficiency mixing system, ozone tail gas processor, etc. The ozone generated by the high-concentration ozone generator is fully mixed with water through the ozone high-efficiency mixing system to achieve the required ozone concentration in the production water, ensuring the safety of the production water.

④ Protein separator

The protein separator effectively utilizes the surface tension of bubbles to separate proteins from the water through a special bubble generation mechanism and water distribution structure, and increases the dissolved oxygen content in the water.

⑤ Ultraviolet sterilizer:

The ultraviolet sterilizer utilizes the property of ultraviolet (UVC) to destroy cells to kill bacteria, viruses, and other microorganisms in the water, achieving a kill rate of over 99.9%. In this system, the ultraviolet sterilizer also helps to eliminate residual ozone in the water, ensuring the safety of the production water.

Related Products

Online consultation

Contact Us

Fax: 020-84234030

Address: No. 81, Donghui Second Street, Huangpu District, Guangzhou

Focus on us

WeChat Public Number