PP Precision Filter Machine

Filtration equipment: PP precision filter machine

Classification:

Product Center

Aquatic Products and Aquariums Series

Aquaculture and aquarium equipment

Filtration equipment

Key words:

PP Precision Filter Machine

PP Precision Filter Machine Details

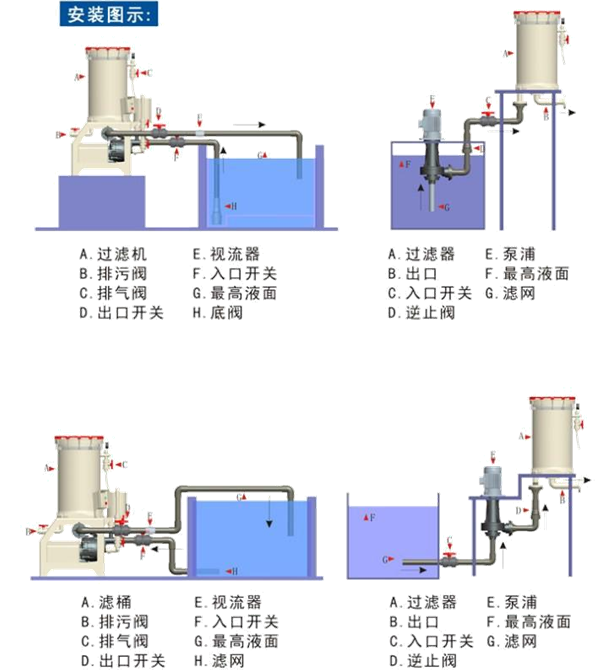

1. Daily Use Precautions:

1. Most electroplating liquids contain hydrogen, which will release hydrogen gas during electroplating. Hydrogen gas can easily remain in the filter cartridge, and if not used for a long time, it will store hydrogen gas, creating internal pressure in the cartridge and even causing a hydrogen explosion. The exhaust valve of the cartridge should be vented daily to release hydrogen gas from the exhaust valve. If not used for a long time, the exhaust valve should be opened to prevent hydrogen residue.

2. Use of the filter machine: When turning on the power, check the outlet for normal flow and clean the filter material regularly. The liquid in the pump can generate high temperatures due to idling, and vapor pressure can build up in the cartridge due to gasification of the liquid. The pressure inside the cartridge can increase due to the release of hydrogen gas, and excessive pressure may pose a risk of cartridge rupture. Remember to check whether the inlet and outlet ball valves of the filter machine are open and whether the pump is idling, as idling can damage the pump and filter machine.

3. Please use the filter machine during working hours. When there is no one operating at night, turn off the power to prevent equipment damage due to idling or blockage of the filter material.

4. Try to avoid placing the machine outdoors, as prolonged exposure of the filter cartridge to sunlight can cause plastic aging and affect its lifespan.

5. The operating pressure must not exceed 1.8KG/c㎡, and the operating temperature must not exceed 70°C.

6. The maximum pressure of the filter machine's pump must not exceed 2.0KG/c㎡.

2. Maintenance and Repair:

1. Operators must be familiar with product performance and be professional repair technicians with repair skills.

2. Regularly check for leaks in the pump and whether there are any abnormalities.

3. Frequently check whether the outlet flow rate is normal, whether the inlet liquid is too low, and whether air is being drawn in.

4. Maintenance personnel should wear acid-resistant clothing and hats before maintenance to avoid injury.

5. Cut off the power before maintenance, close the pump inlet, and discharge any gas and liquid from the pump.

6. When disassembling the pump, the impeller fixing screws should be tightened clockwise. The distance between the impeller and the front cover should be about 1.5mm; if it is too small, it will cause friction and damage the pump. The gap between the impeller and the rear cover should also be maintained at around 1.5mm.

7. During assembly, the ceramic fixing ring of the shaft seal should be aligned with the center of the shaft.

8. When tightening the screws of the rear cover and the main body, do not apply excessive force to avoid damaging the pump.

PP Precision Filter Machine

Related Products

Online consultation

Contact Us

Fax: 020-84234030

Address: No. 81, Donghui Second Street, Huangpu District, Guangzhou

Focus on us

WeChat Public Number