Fully Automatic Valve-less Filtration System

The principle of the fully automatic valve-less filtration system is based on the self-purification phenomenon of water bodies that objectively exist in nature

Classification:

Product Center

Aquatic Products and Aquariums Series

Treatment and Recycling of Aquaculture Farm Wastewater

Key words:

Fully Automatic Valve-less Filtration System

Fully Automatic Valve-less Filtration System Details

Changchi Company has conducted extensive practice and experiments on the CC-SC-JL series fully automatic valve-less filtration system, inventing the use of corrosion-resistant and aging-resistant UPVC material to replace the short-lived steel products, achieving a service life of over 20 years. The filtration medium uses multi-layer composite filter materials instead of single quartz sand, increases aeration and oxygenation equipment, and reduces backwashing time from the previous 5-8 minutes to the current 2.5 minutes, with thorough and clean backwashing and high automation. This product can achieve both fine filtration and oxygenation effects, featuring functions such as environmental protection, energy saving, water saving, and reducing later operating costs.

1. Principle Introduction

The principle of the fully automatic valve-less filtration system is based on the self-purification phenomenon of water bodies that objectively exists in nature, integrating various advanced water treatment technologies into a new type of water treatment equipment. The specifics are as follows:

Theoretical Basis: The self-purification of natural water bodies occurs through the evaporation of surface water under the sun, forming clouds that fall to the ground through rainfall. After undergoing multi-layer filtration through the strata, it converges into underground runoff, which then flows out in the form of clean spring water for human use or merges into other bodies of water (repeating the cycle). During this process, due to changes in terrain elevation, some oxygenation processes (such as waterfalls) are naturally completed, continuously enhancing the water's self-purification ability. The saying "running water does not rot" reflects this principle.

This treatment system integrates the water treatment theories and related technologies involved in water self-purification, such as the naturally formed repeated composite filter layer of strata and hydraulic automatic aeration and oxygenation technology. It also maximizes some characteristics of hydraulics, such as utilizing the siphon phenomenon to achieve automatic control of the backwashing process, using height differences to realize automatic filtration in the system, and integrating hydraulic clarification tanks.

2. Brief Introduction to the System Working Principle

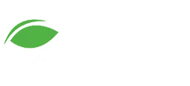

The water to be treated is sent into the upper automatic aeration and oxygenation of the fully automatic valve-less filtration system through the inlet pipe, filtered from top to bottom through the filter layer, and the filtered clean water is stored in the clean (washing) water tank through the connecting pipe. Once the tank is full, it enters the outlet trough, where the water is aerated and oxygenated again through the spiral aeration device in the outlet trough.

When the filtration system is in operation, the filter layer continuously retains suspended solids, and the resistance of the filter layer gradually increases, prompting the water level in the siphon rising pipe to continuously rise. When the water level reaches the mouth of the siphon auxiliary pipe, the water falls from that pipe and continuously draws air from the siphon descending pipe through the exhaust pipe, creating a vacuum inside the siphon pipe, resulting in siphoning action. Thus, the water in the tank is filtered from bottom to top through the filter layer to backwash the filter material. At this time, the filtration system is still taking in water, and after backwashing begins, both the inflow and the washing wastewater are discharged through the siphon rising pipe and descending pipe to the drainage well. When the water level in the washing tank drops to the mouth of the siphon break pipe, air enters the siphon pipe, breaking the siphoning action, ending the backwashing of the filtration system, and the filtration system returns to normal, automatically proceeding to the next cycle of filtration operation.

3. System Working Process

Step One: Aeration and Oxygenation

The water to be treated is pumped into the upper automatic aeration and oxygenation tank of the system for full oxygenation. During the automatic oxygenation process, sufficient oxygen is inhaled while harmful gases such as ammonia and nitrogen in the water are separated out, allowing the water to come into full contact with the oxygen in the air, enhancing the coagulation of pollutants in the water, thus preparing for the next step.

Step Two: Fine Filtration

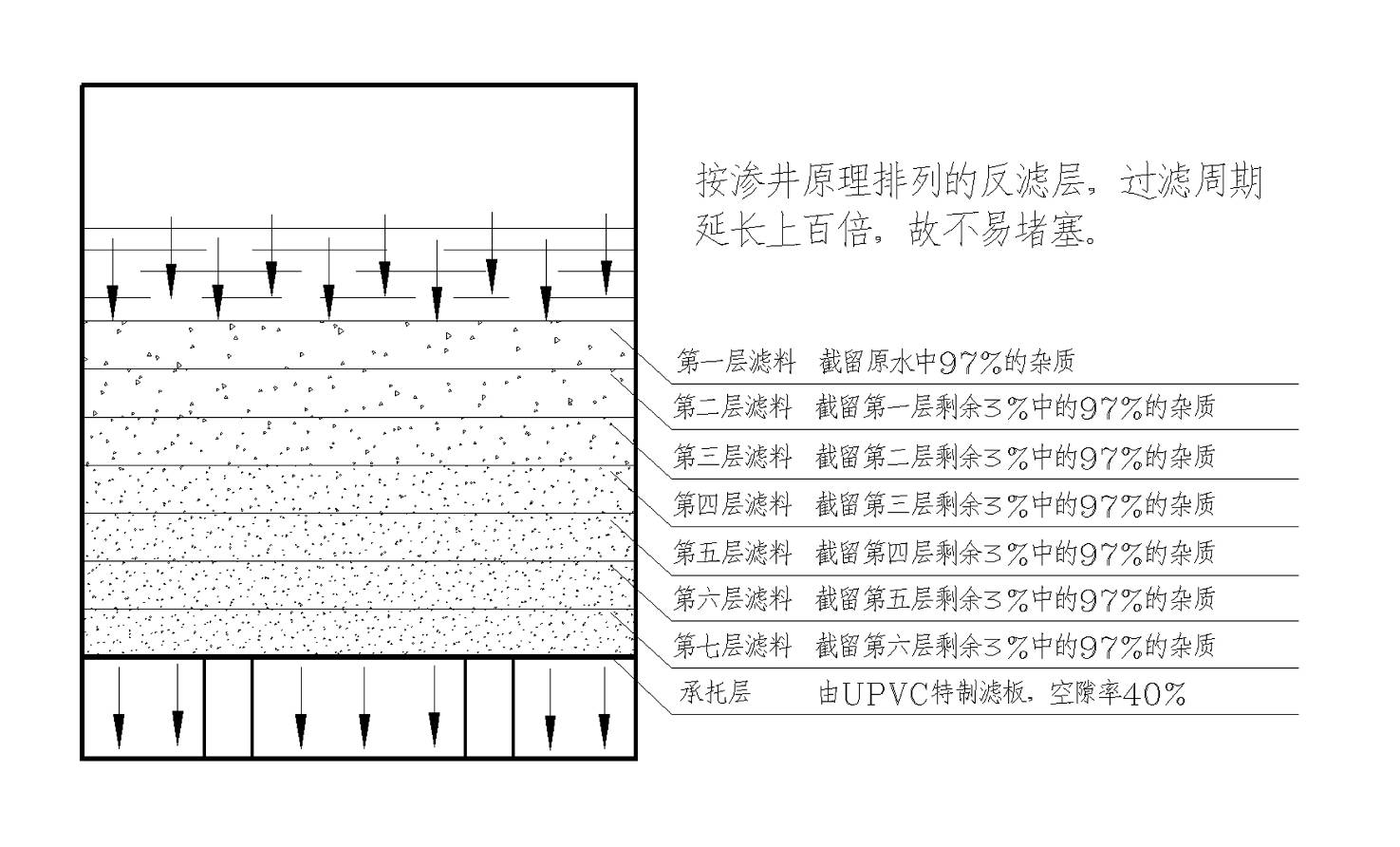

The water after aeration and oxygenation flows into four fine filters through the distribution water tank for filtration. Since the filter layer is made of different mineral materials arranged from large to small by particle size, forming a 7-layer composite filter layer, the filtration system will not penetrate the filter layer due to increased pressure, and during the continuous interception of pollutants, the filter layer quickly forms a thin biological film that can further decompose organic and inorganic substances in the water. Additionally, the minimum particle diameter of the filtration medium is 0.25 mm, which is much smaller than that of quartz sand filter material, resulting in a strong interception capability, thus achieving a turbidity of the effluent of up to 1 NTU.

Step Three: Organic Matter Separation

When the source water, which produces a large amount of foam during aeration and oxygenation, reaches the filter layer, the foam, being lighter than water, floats above the water surface. The pressure inside the equipment is very low, and the filter layer uses composite filter materials with smaller particle sizes and larger specific gravities, preventing the foam from passing through the underlying filter layer, which can only float on the surface. As the foam accumulates, it can only overflow through the upper pipeline, or when the filter pool is backwashed, the foam is washed away, thus effectively removing organic pollutants such as nitrogen, phosphorus, and grease from the water, achieving the separation of organic matter.

Step Four: Fully Automatic Backwashing

After the water has undergone the above two processes, it enters the fine filter layer designed according to the principle of infiltration wells. Impurities, algae, and algae spores in the water are retained on the surface of the filter layer, and the water is purified after flowing through the filter layer. When the impurities retained on the surface of the filter layer accumulate to a certain extent, the water treatment equipment automatically completes the backwashing of the filter material. After backwashing, the filter material automatically resets, restoring the fine filtration function. The entire process is automatically completed under hydraulic action, requiring no manual operation.

Step Five: Long-lasting Sterilization

The equipment is equipped with a disinfectant dosing system that can add disinfectants to the water during the treatment process according to water use requirements, to kill algae and bacteria in the water, providing continuous sterilization and algae-killing effects for circulating water. Ultraviolet sterilizers can also be used to disinfect the treated water, which can be visually understood as providing "immunity" for the water body.

<1>Aeration and Oxygenation Principle

Aeration and Oxygenation Schematic Diagram

In the aeration tank, the source water rises through the internal channel, overflowing at the top into a 360-degree radiation water tank. In the tank, the water flow splits into three parts and falls, forming three extremely thin water curtains in the air. According to the principle of oxygen transfer, to increase the overall oxygen transfer coefficient, it is necessary to enhance the turbulence of the water flow liquid phase, reduce the thickness of the liquid film, accelerate the renewal of the gas-liquid interface, and increase the contact area between gas and liquid. In other words, the water flow is sufficiently subdivided, increasing the contact area between the water flow and the air, allowing for full aeration in the air, resulting in water rich in dissolved oxygen, while harmful gases such as organic matter, nitrogen and phosphorus-containing substances, ammonia, and carbon dioxide overflow from the water surface. Since the oxidation-reduction process is the main action for water purification, the dissolved oxygen in the water can react violently with pollutants, thereby removing harmful substances from the water. According to water quality testing, the dissolved oxygen in the treated water remains in a saturated state, keeping the water fresh and activated.

<2>Principle of Organic Matter Separation

Schematic Diagram of Protein Separation

The reason for the formation of foam on the water surface is that organic pollutants such as surfactants in the water act as foaming agents, which include urea, nitrogen (N), phosphorus (P) substances, and oils. In the CC-SC-JL series fully automatic valve-less filtration system, when the source water mixed with foam reaches the filtration layer, the foam floats above the water surface because it is lighter than water. The pressure inside the equipment is very low, and the filter layer uses composite filter materials with smaller particle sizes and larger specific gravities, preventing the foam from passing through the lower filter layer, allowing it to only float on the surface. As the foam accumulates, it can only overflow through the upper pipeline, or when the filter pool is backwashed, the foam is washed away, thus effectively removing organic pollutants such as urea, N, P substances, and oils from the water.

<3>Filtration (Siphon Filtration) Principle

Schematic Diagram of Siphon Principle

The composite multi-layer filter material is filtered according to the grading of the siphon principle, with water flowing from top to bottom under gravity. The first layer has a particle size d1=0.8~1.6mm, specific gravity r1=2.4, thickness h1=300mm; the second layer has a particle size d2=0.4~0.8mm, specific gravity r2=3.2, thickness h2=200mm; the third layer has a particle size d3=0.2~0.4, specific gravity r3=4.2, thickness h3=170mm; the fourth layer... The first layer retains 97% of the heavier particles, leaving 3% of the remaining particles, the second layer retains 97% of 3% of the heavier particles, and so on. The thickness of the first layer of filter material is the largest, with each subsequent layer decreasing in thickness, allowing each layer to pass through 3% of the weight, with no layer being completely blocked, all having gaps. The last layer still has gaps, but at this point, the turbidity is less than 1 degree, and there is no need to increase the number of filtration layers.

The characteristic of siphon filtration is that although the sewage has a high concentration and a large amount of pollutants, it will not clog over long-term use and will continue to allow water to seep through. The precision filtration system designed according to this theory has the same efficiency, is not easily clogged, and does not require frequent backwashing, greatly extending the working cycle.

The basis for the grading of the siphon backwash layer is focused on the characteristics of the sewage itself. The particle size of the filter layer matches the dispersed particles in the sewage. The dispersed particles in the sewage can be arranged into many levels according to their size, with the normal relationship being that the larger particles in one level and the smaller particles in the adjacent level have a basic relationship of 97% and 3%. The larger particles retained by the upper layer and the smaller particles retained by the lower layer exist in a subtle proportional relationship, where the weight of the particles retained by the upper layer accounts for 97% of the total weight, while the number of particles only accounts for 3%, and the weight of the particles retained by the lower layer is 3% of 97%, and so on. This is the reason for the composite filter material layer graded according to the siphon backwash layer, which retains particles in the sewage layer by layer, creating distance, ensuring that no layer is blocked, extending the working cycle, and effectively improving the water quality.

Due to the characteristics of this layered filtration, it can achieve a bacteria removal rate of over 90%. It is well known that the particle size of Escherichia coli is 0.5μm; in other words, this composite filter layer can remove all particles larger than 0.5μm, effectively removing those larger than 0.5μm.

<4>Automatic Backwash Principle

Water passes through the filter layer, and impurities in the water are intercepted and accumulated, increasing the resistance of the filter layer, causing the water level to rise. When the water level rises to a certain height, the water passes through an auxiliary siphon pipe, forming an automatic siphon throughout the system, and the equipment backwashing begins. Through an automatic timing device, the backwashing lasts about 2.5 minutes to achieve the backwashing effect. Therefore, the backwashing working cycle depends on the water quality, and the washing cycle can range from several hours to several months.

4. System Features

4.1 System hydraulic automation, no valves, no operation, utilizing hydraulic automation principles to complete aeration, oxygen dissolution, flotation, seven-layer filtration, and backwashing processes without the need for dedicated management personnel.

4.2 Forward-looking technology, leading similar products in the world, saving 70% of water and 90-100% of chemicals.

4.3 All pressure-free water treatment, with a circulating water pump lift generally of 6-8 meters, low energy consumption, and saving over 80% of electricity compared to other types of water treatment equipment, significantly reducing operating costs.

4.4 The equipment structure is compact, installation space is concentrated, occupying a small area, saving 50-70% on civil construction.

4.5 The dissolved oxygen of treated water is ≥5mg/l, thus freshening and activating the water quality, with an effluent turbidity of 0.4-1, suitable for the natural growth of fish.

4.6 Timely backwashing based on the internal interception of pollutants in the equipment, with uninterrupted water supply during the cleaning process, minimal pipeline pressure loss, effectively removing foam from the water—i.e., removing organic substances (including phosphorus, nitrogen, and other foaming substances) to maintain good water quality, making the water surface shimmer and reflect blue waves.

4.7 The equipment backwashing lasts a short time (about 2.5 minutes), has a high backwashing intensity (32l/㎡.s), and uses little backwashing water.

4.8 The equipment does not require regular maintenance and consumable replacement, with the main system equipment guaranteed for over 20 years.

5. System Application Range

The CC-SC-JL series fully automatic valve-less filtration system can be widely used in the treatment of landscape water bodies, aquaculture, and swimming pools, especially in aquaculture water treatment, where it can play a dual purification role of mechanical filtration and organic matter separation, while also effectively oxygenating the cultured water.

6. Equipment Selection Table

Related Products

Online consultation

Contact Us

Fax: 020-84234030

Address: No. 81, Donghui Second Street, Huangpu District, Guangzhou

Focus on us

WeChat Public Number